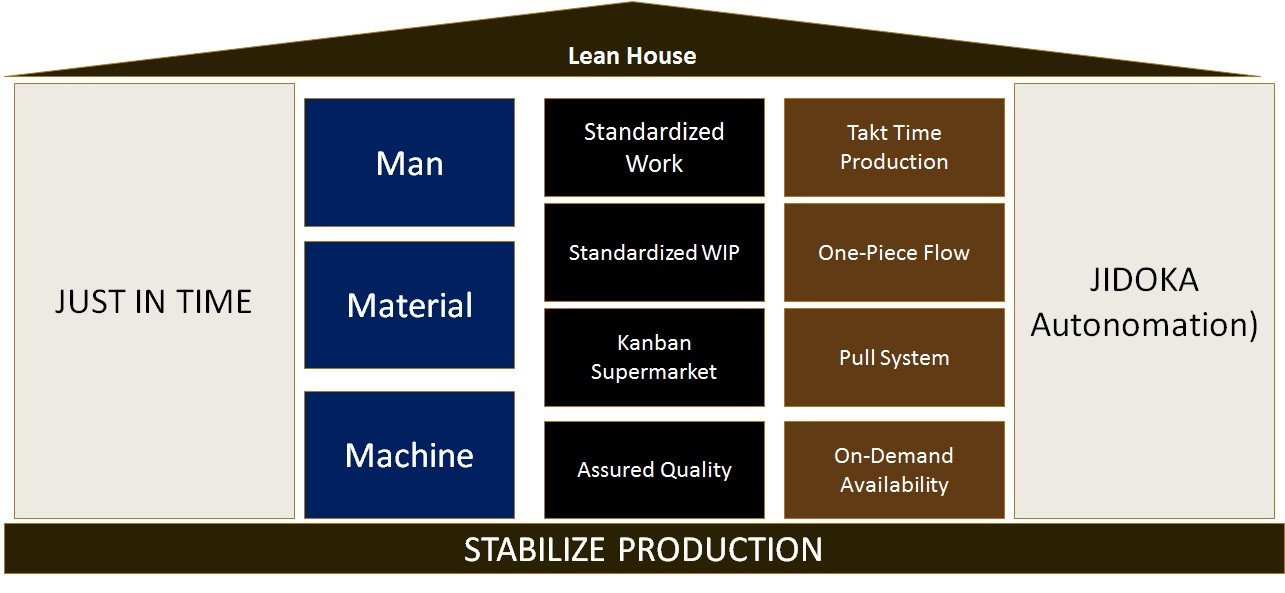

Lean methodology is a way of ensuring that all Assets like People, Plant, Equipment, Raw Material, Utilities are used only to produce value to the customer. This is done by identifying and eliminating inherent waste in every activity.

There are seven types of waste which have to be minimized or eliminated:

- Waste of Over Production

- Waste of Processing

- Waste of Motion

- Waste of Conveyance

- Waste of Repair

- Waste of Waiting

- Waste of Inventory

This course gives a systematic way of reducing the seven types of waste. The instructor has been directly trained by Sensei who were part of the original Toyota Production System.

This will benefit Senior Management, Plant Management, Maintenance Professionals, Shop Floor Engineers and Quality Professionals.